Our specific benches are produced based on generic product building blocks developed around the following areas:

- A homogeneous bench architecture that covers:

- The various V-model phases: from V&V to Production and even Maintenance.

- The various subscriber programmes.

- A catalogue of high-added-value hardware and software components that can be deployed on all stock.

- Open to third-party ecosystems that can be used to integrate hardware and software building blocks developed by third parties.

- Benches that can be reconfigured to effectively adapt stock to the demands of the various programmes.

Find out more

A multi-functional bench: Enables Hardware, Software and System integration testing, to better monitor the various programme life-cycles. The bench therefore supports programmes from the fully simulated phase to the HIL phase, retaining the same testing scenarios. We can therefore record the results of one of the phases and compare it to another, and even have them running at the same time with the same inputs to compare their results. The scenarios can be reused between these phases.

A multiple-programme reconfigurable and modular bench: The architecture, based around disconnectable chairs and modular I/O racks is used to easily change the bench target, and resize it as necessary. This changes the bench, so it can go from one programme or system to another.

Adaptable and modifiable configuration of the channels using software: Channel assignment can be configured in the HMI and managed per programme.

Advanced analysis and troubleshooting capacities: During hardware testing and troubleshooting, it is possible to create diagrams for a channel that were not necessarily provided for in the design (parasitic impedance, signal injection, etc.). It is also possible to redirect all bench analogue inputs to multimeters or oscilloscopes. These capacities enable significant time savings during hardware issue diagnostics.

Configuration of the testing equipment thanks to a description of the interfaces for the items being tested: Aircraft ICDs can be directly imported into U-Test to be more responsive when there are new standards or updates. Various importers already exist: Airbus, CAN DBC, etc. and it is simple to create new ones.

An upgradeable bench: The bench can accommodate an HIL hydraulic rack to control the aircraft actuators when testing computer models. This bench could also control antagonistic actuators during testing with actual computers. In particular, the number of I/Os can be modified based on need, by adding/removing racks.

Generic and dedicated graphical interfaces: The basic graphical interfaces in our HMIs are used to display all the values. It is also possible to create block diagrams dedicated to a function very easily (cockpit, hydraulic network, etc.), which can be used in any web browser (PC, laptop, tablet, etc.)

An effective and mature software ecosystem: Our solution is based on the U-TEST® software for system integration tests and FEATS software for hardware integration or for automatic testing.

A bench that can manage multiple-session aspects, which creates opportunities for the following use cases:

- making real-time comparisons with golden unit type items,

- performing go/no-go tests on several computers at the same time if necessary (same type or different type).

- Most internal wiring is made up of off-the-shelf cables, everything is generic, only the patch panel PCB is generated for the configuration.

- Most self-tests are generated automatically.

- The “process-as-designed” patch panel PCB

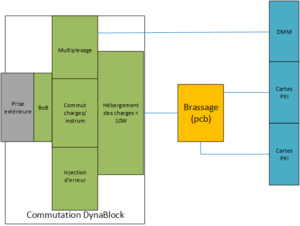

The core of the architecture: DynaBlock Switching

The DynaBlock switching system is taken from the SPHEREA ATEC® Dyna series family of benches, which are used in particular by a major French equipment manufacturer for production testing and troubleshooting for engine computers.

This switching system is the core of the bench hardware architecture. It is used to elegantly solve architectural issues, which can occur on an integration bench, minimising specific developments:

- Integration of an interface multiplexed to high-precision instrumentation (multimeter or oscilloscope type) that can be used in sequential testing or for bench calibration

- Integration of an electrical pattern generation cell (DENG, for Dynamic Electrical Network Generation) applicable to all channels and channel combinations used for fault injection, multiplexed measurement and bench self-testing

- Simple integration of load boards at the inputs/outputs of the computer being tested

- Connectors with parallel generation/simulation resources for an HIL integration bench

- Connectors with the UUT built into the frame

- Integrated Break-Out Panel

The DynaBlock frames can be chained to make up a switching system suited to the size of the system being tested.

We pay special attention to the assignment of the harnesses on the Dynablock frame, to favour 1:1 or Y topologies between the bench and the computer connectors.

The Break-Out Panel on the front side of the DynaBlock frame will have markings indicating the assignment of the channels at the connectors.

Patching via PCB

Using PCBs to patch points considerably reduces costs, production lead times and integration risks. The PCBs are generated automatically via the Spherea “CrossBlock” tool.

There are significant positive impacts and major advantages to this technology on the inner bench wiring:

- Specific wiring developments are eliminated

- Unit wiring tests are eliminated; we can directly test the different connections at self-test level as the PCBs and off-the-shelf cables are tested in the factory

- The development/manufacturing lead time is shortened

- The wiring error risk is eliminated (except for design errors)

- Wiring maintenance operations are easier, faster and rarer. It is simple to replace a cable as all cables are made up of a point-to-point connection.